CASE STUDIES

1

Aerospace tool

Product : Fixture strong back, LPT assy

Material : Super Duplex

Size : 1300 X 1300 X 400mm

Challenges

- Machining super dulex material for a welded assembly

- 7 stages of welding and 10 stages of machining for one weld assembly, whilst maintaining assembly tolerance through the process

- Complex welding fixturing

- 6 proof load tests at varaition

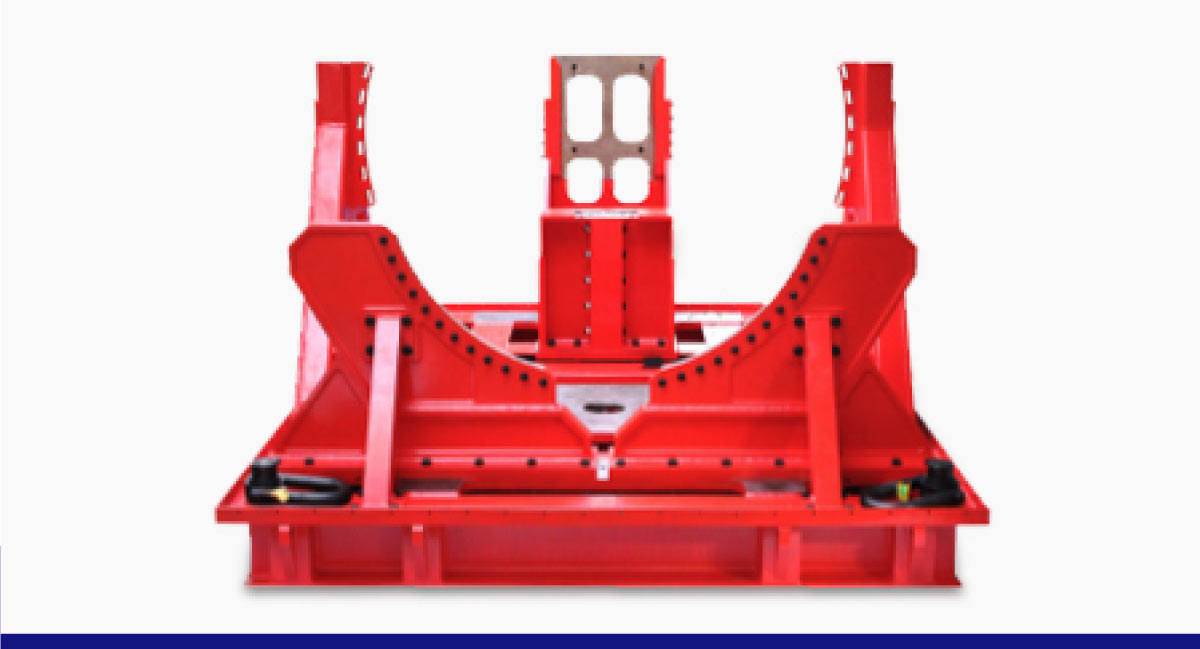

2

Engine transportation stand – power gen gas turbine

- Proof load test of 70 tons

- Tool weight – 8 tons

- Dissimilar metal welding between heat treated 4140 and carbon steel

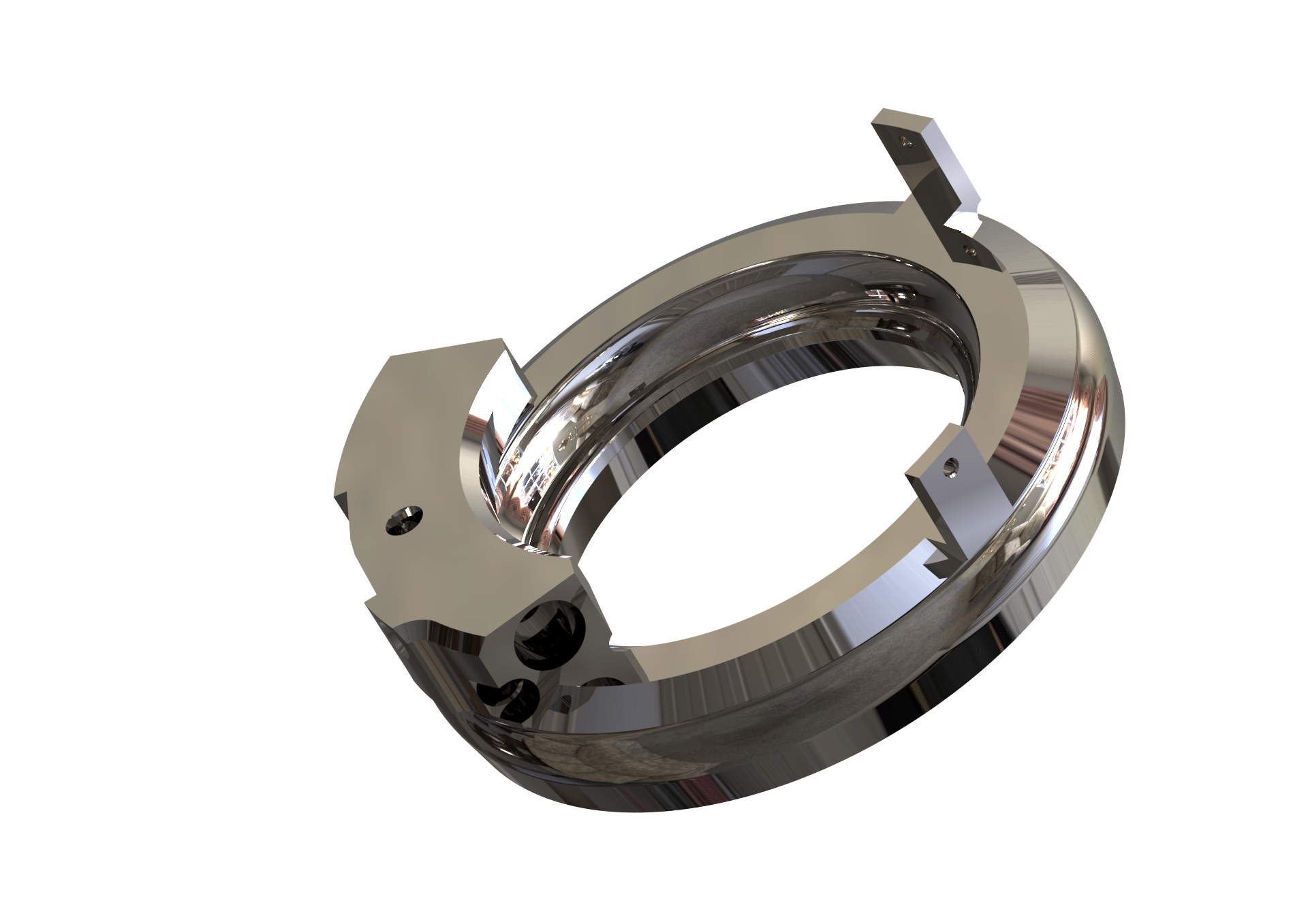

3

Defense component

Product : Manifold

Material : Ti-AL-4V

Size : 180mm

Challenges

- Challenging face groove turning to maintain thickness of 1.7mm +-0.05 & 2.05mm +-0.05

- Very high pressure critical cross-sectional area

- 2mm +- 0.02 , 6mm +- 0.015 , 4.4mm +-0.02 : Difficult to obtain consistent dimensions & close tolerances due to titanium material.

- Very high L/D ratio of tool – deep holes +85mm

4

Space component

Product : Head End Dome

Material : Ti 6AL 4V

Size : 317 X 130 mm thick

Lead time FAIR : 40 days

Challenges

- Concentricity of 0.1 mm on all diameters

- Surface finish of 0.8 RA on all highlighted areas

- 5th axis machining of 3 x 6.0 mm holes & intersected with pyro port holes

- 70% material removal with several stages of machining + aging

- 3D profile machining to ensure seamless transition between turning and milling centers