1. FACILITIES

Unimech manufactures a wide range of products for the aerospace, semiconductor and energy sectors. Our product offerings include aero-tooling, precision parts, assemblies, electro-mechanical subsystems for nuclear reactors, and semiconductor manufacturing equipment.

Unit I, Peenya

Our Unit I facility in Peenya, Bangalore, spans over 30,000 sq. ft. and is equipped with a temperature-controlled machine shop. It features Computer Numerical Control (CNC) turning and milling machines, as well as Capability Maturity Model (CMM) capabilities, ideal for machining highly complex component parts for energy and aerospace customers.

Unit II, SEZ Facility, Devanahalli

Our Unit II facility is Located in a Special Economic Zone (SEZ) near Bangalore International Airport, our Unit II facility covers over 90,000 sq. ft. and is equipped with turnkey capabilities for machining, fabrication, assembly, and other special processes. We are in the process of expanding this facility to meet growing demand. This facility primarily focuses on aerospace tooling, complex manufacturing solutions, and machining complex component part for global OEMs and licensees.

2. MACHINING CAPABILITIES

Our integrated design, engineering, and production capabilities, combined with expertise in developing customized solutions in industries like aerospace, allow us to deliver high-quality solutions to our customers.

3 Axis CNC

Max X axis travel – 1260mm

Max Y axis travel – 610mm

Max Z axis travel – 610mm

4 Axis CNC

Max X axis travel – 2200mm

Max Y axis travel – 1400mm

Max Z axis travel – 750mm

5 Axis CNC

Max X axis travel – 800mm

Max Y axis travel – 450mm

Max Z axis travel – 500mm

CNC Turning

Swing over dia – 648mm

Swing over bed length – 1118mm

RPM – 2400

CNC Turn Mill

Swing over dia – 426mm

Swing over bed length – 571mm

RPM – 4000

CNC VTL

Swing over dia – 1600mm

Swing over bed length – 900mm

Conventional VTL

Swing over dia – 350mm

Swing over bed length -1000mm

RPM – 1235

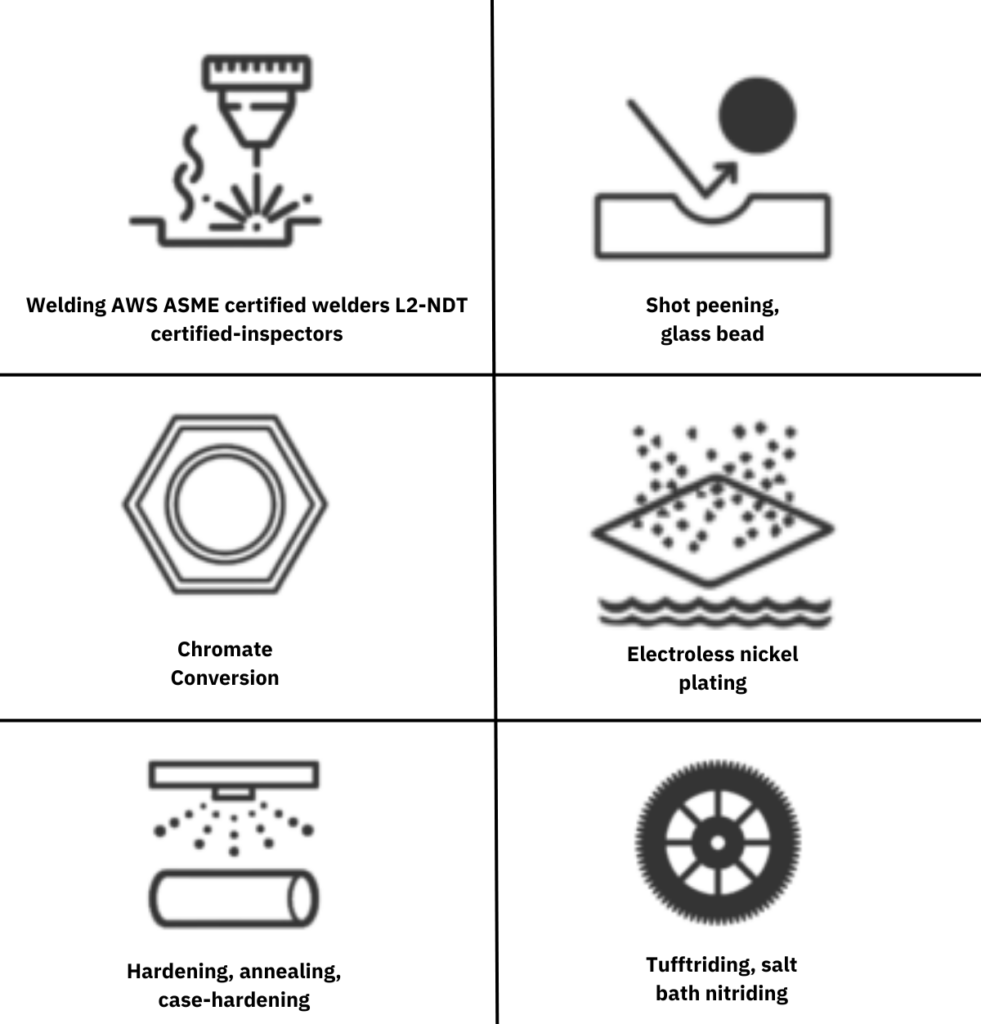

3. SPECIAL PROCESS CAPABILITIES

We are recognized for our ability to produce complex components, high-precision fabricated assemblies, and advanced tooling solutions, particularly sought after by key players in the aerospace sector. Our comprehensive range of special process capabilities is available both in-house and through a robust network of trusted vendors. This enables us to meet the stringent quality and performance standards required in the aerospace industry, ensuring reliable, precise, and durable products.

Welding AWS ASME certified welders L2-NDT certified-inspectors

Shot peening,

glass bead

Chromate

Conversion

Electroless nickel plating

Hardening, annealing,

case-hardening

Tufftriding, salt

bath nitriding

Vacuum hardening

Black oxide or black

phosphate

Anodizing: Hard, clear, black,

gold and red

Plating: Zinc, cadmium,

electroless nickel

Delta top coating

Coating: Nylon, teflon, rilsan, halar,

PVD etc

Marking: Machine engraving,

laser, stencil

Painting

4. TOLERANCE ACHIEVABLE

CNC Turning Tolerance Capability

Job Size

10 – 250mm

250 – 500mm

500 – 2000mm

Position

0.015mm

0.025mm

0.035mm

Max surface finish

Ra0.4

Ra0.8

Ra0.8

Flatness/ Parallelism

0.01mm

0.02mm

0.03mm

CNC Turning Tolerance Capability

Job Size

10 – 250mm

250 – 500mm

Above 500mm

Diameter

0.005mm

0.015mm

0.025mm

Max surface finish

Ra0.4

Ra0.4

Ra0.8

Total runout against datums

0.005mm

0.01mm

0.02mm

Precision Weldments & Machining Jobs

With our robust vendor network and in-house capabilities, we are able to efficiently scale production and deliver complex components, high-precision fabricated assemblies, and tooling products with very tight tolerances

5. ELECTRONIC AND ELECTRICAL CAPABILITIES

Our electronics clean room enables us to build electrical & electronic components together with full mechanical integration & quality assurance testing.

- Full mechanical integration & quality assurance testing

- Internal wiring harness & interconnection (ETFE, PVC)

- Test console hardware & software integrations

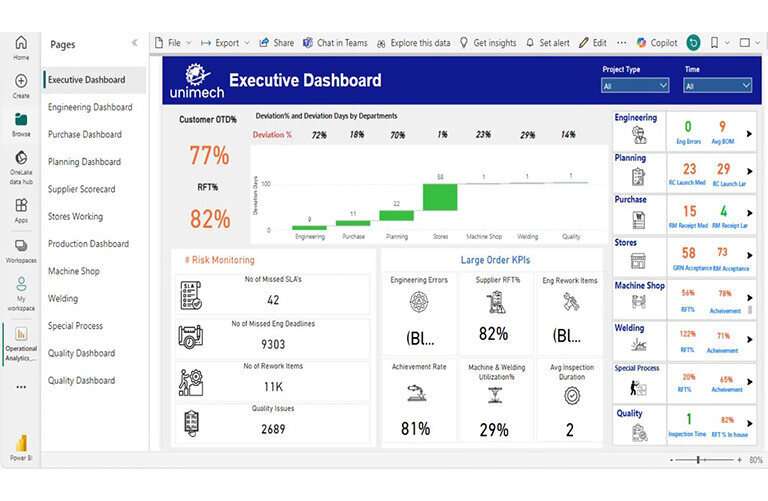

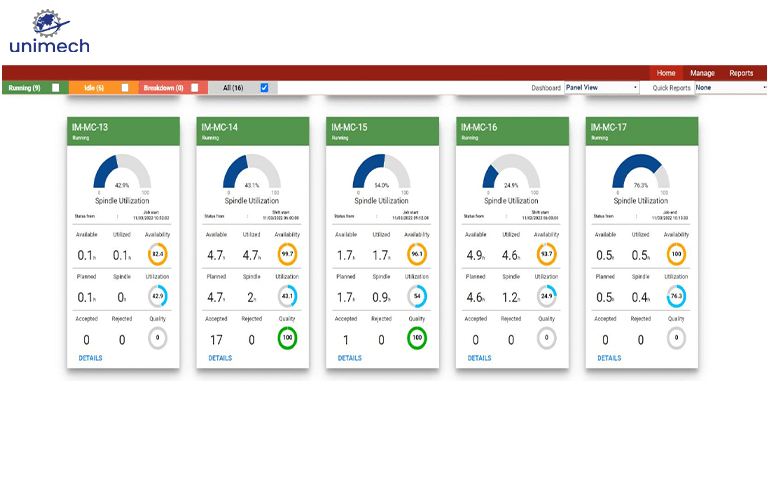

6. DIGITAL MANUFACTURING SYSTEMS

We deploy a comprehensive digital manufacturing system that seamlessly integrates every stage of the process, from order origination to final delivery. This system captures all inspection requirements and measurements, reinforcing our commitment to maintaining the highest standards of quality.

In addition, we have developed an in-house ERP system that meticulously plans and tracks each step of the product manufacturing journey. This includes managing the movement of components to external vendors and ensuring their timely delivery, allowing us to meet deadlines and deliver products efficiently.

ERP SYSTEM

DIGITAL DASHBOARD