Industry

Unimech provides safety-critical electro-mechanical sub-systems and specialist inspection tools for nuclear power station new builds and operators. We support major OEMs, including the Nuclear Power Corporation of India. We follow ISO-certified processes to manufacture and integrate electrical and electronic product requirements, including computer-controlled mechanical systems, electric motors, thermostatic and temperature control equipment, and hydraulic devices.

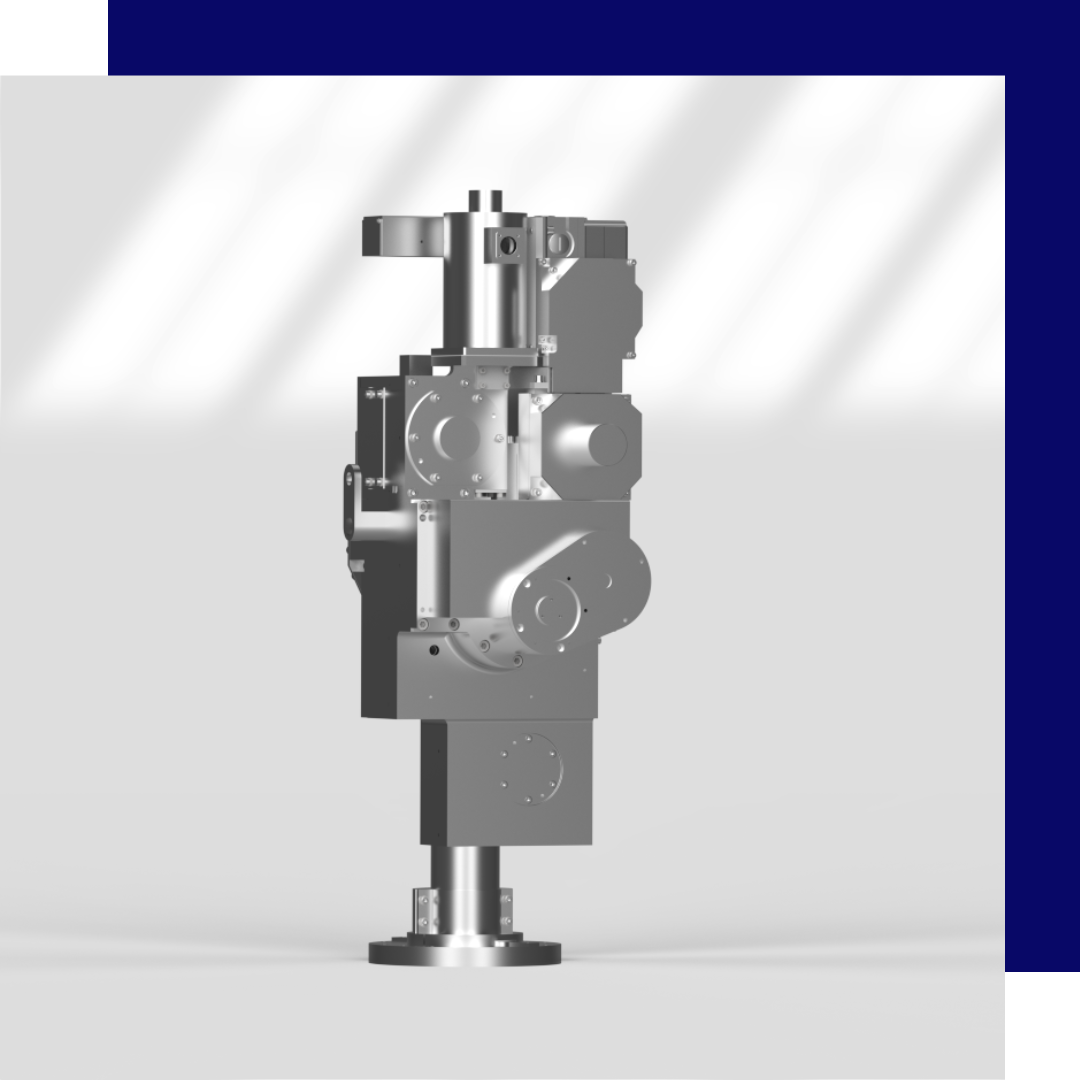

NUCLEAR REACTOR CONTROL SUBSYSTEM

Drive mechanisms to operate reactor shutoff rods the material used is ss304 and 17-4 forgings and castings, the quantity is 120+, and the project size is >$4m. Drive mechanisms to operate reactor shut-off rods are for Manufacturing, integration, and testing process. The electrical integration challenges are the soldering process critical for nuclear-grade reliability. There is further complexity in mil grade circular connector assembly, integration of motors, variable potentiometers, EM clutch, and limit switch assembly. In addition, another challenge is the custom Reed switch assembly with encapsulated Reed switch setup and qualification of the assembly sensitivity.

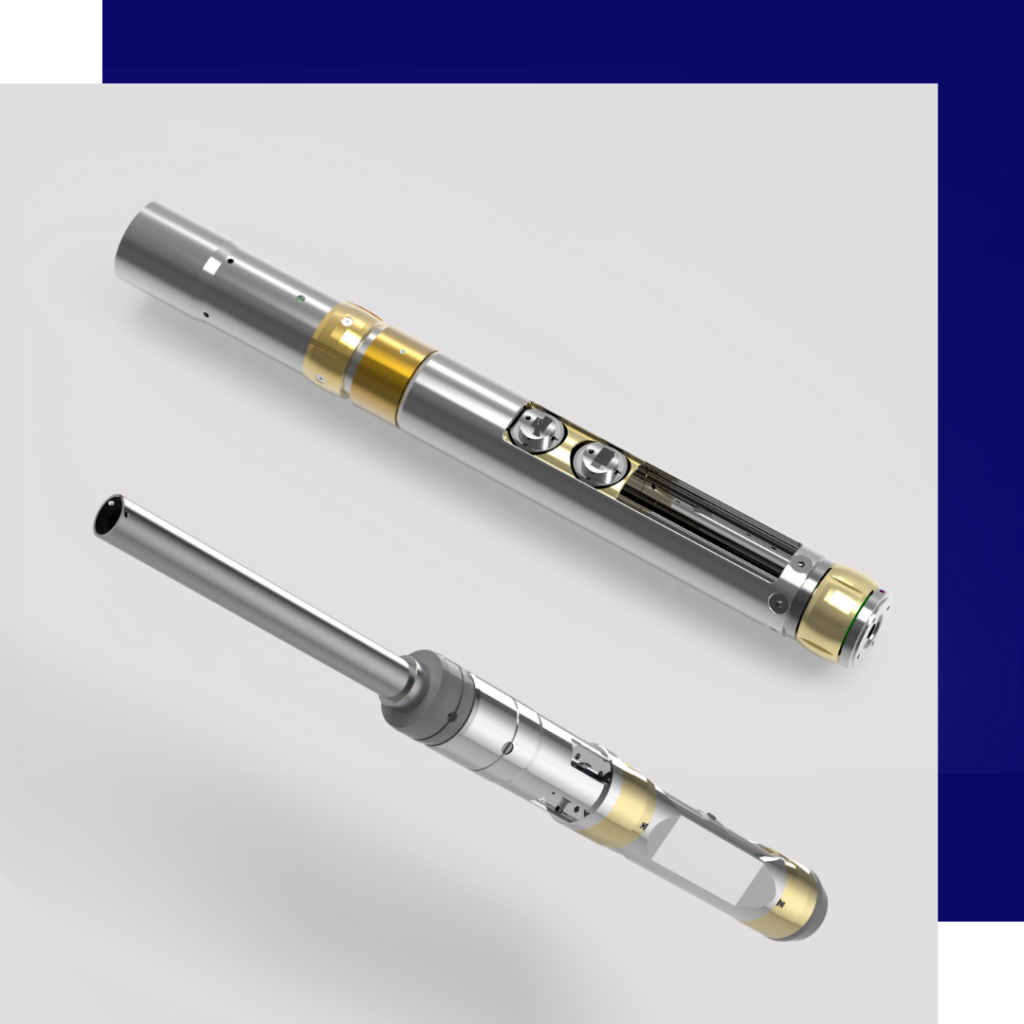

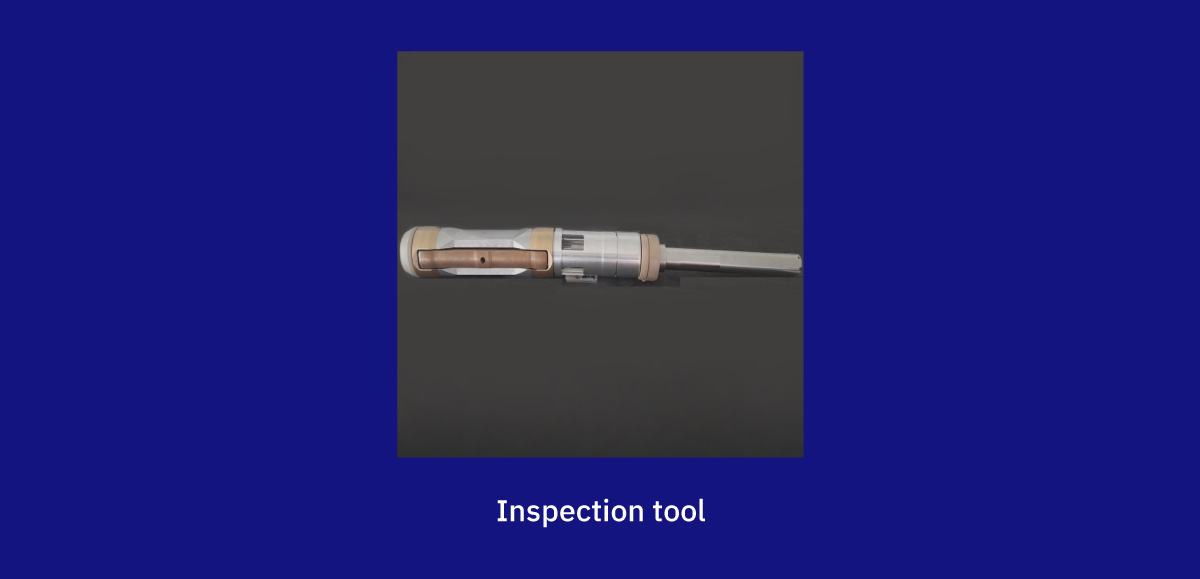

Measurement tool to establish hydrogen pickup rate in the reactor tubes

Applications

Equipment qualification is an extremely important factor for nuclear power companies, both in terms of new builds and maintenance and refurbishment programs for existing systems. An excellent command of the testing and verification process is essential to ensure the delivery of effectively qualified equipment while optimizing lead times and costs, and Unimech can do it all with aplomb.

Requirements

Unimech Aerospace is an ISO9001 and ISO45001 certified company. Our engineering capability, in-depth understanding of complex specifications, 100% inspection, and exceptional focus on zero defects ensure our parts or assemblies are delivered to drawing. We offer fully tested electro-mechanical assembly for fulfilling varied customer needs. We have in-house electro-mechanical capabilities with high-end custom solutions including the quality control systems for rigorous and qualified testing of electro-mechanical assemblies

Unimech, a trustworthy manufacturing partner

At Unimech, all projects undergo 100% quality checks, final inspections of features, visual checks, proof load tests, leak tests, and non-destructive tests in order to check the assembly or tool is fully fit for function and safety. Inspection reports, and traceability documents are delivered with the products. All our raw materials are procured to international standards and independently checked by our NABL accredited lab.

At Unimech, all projects undergo 100% quality checks, final inspections of features, visual checks, proof load tests, leak tests, and non-destructive tests in order to check the assembly or tool is fully fit for function and safety. Inspection reports, and traceability documents are delivered with the products. All our raw materials are procured to international standards and independently checked by our NABL accredited lab.